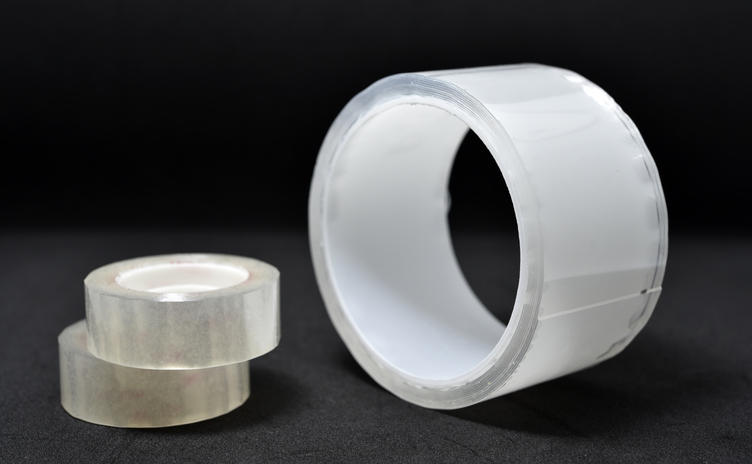

Composite release tape is specifically designed to make the processing of composite parts faster, easier, and more affordable. Heat shrink release tape is used to apply pressure to the composite to optimize the surface finish and fiber consolidation. It can have a release coating which allows the tape to be easily removed from the composite without leaving a residue.

How to Know if Composites Release Tape is Right for You

Application

Knowing what your composites release tape will be used for is critical to knowing what the best option is for you. If your composite requires a high-quality lamination and a void-free cure, and if you are looking to use less material during the application process, Hi-Shrink Tape maybe a good fit. These tapes are a great alternative to vacuum bags and autoclaving operations, and they offer various benefits — including producing a clean, resin-rich surface finish; improved consolidation; and reduced porosity of the composite.

Composite Part Design

Depending on the shape and geometry of your composite part, Hi-Shrink Tapes could be the perfect fit. Hi-Shrink Tape tends to work best on composites and parts with simple geometry. If you have more complex shapes, options may still be available — simply work with Dunstone to explore custom possibilities.

Cure Temperature

Depending on your composite and its application, you may not need to use ovens or autoclaves in order to achieve optimal consolidation and compressive force. Dunstone’s Hi-Shrink release tape starts to shrink at 70ºC and reaches its maximum shrink force in the 120ºC to 160º C range depending on the type of tape used. We carry various tapes for all temperature requirements:

- The 100 Series, 200 Series, 300 Series, and 500 Series are made of Mylar/polyester film and have a cure temperature of up to 165ºC

- The HT Series is made of ETFE film and has a cure temperature of up to 180ºC

- The X Series is made of Kapton/polyimide film and has a cure temperature of up to 400ºC

Shrink Percentage

Your composite’s release tape must fit tightly in order to prevent air bubbles, voids, or improper shrinkage. Selecting the right shrink percentage for your application and product can reduce the risk of these abnormalities occurring. At Dunstone, our tapes have various shrink percentages so you get the best fit:

- The 100 Series comes with shrink percentages of 6%, 12%, and 20%

- The 200 Series comes with shrink percentages of 5%, 10%, 12%, and 20%

- The 300 Series comes with shrink percentages of 12% and 20%

- The 500 Series comes with shrink percentages of 15% and 20%

- The HT Series comes with a shrink percentage of 12%

- The X Series comes with a shrink percentage of 8%

Trust Dunstone for Your Composites Release Tape Needs

With more than 60 years of experience, Dunstone is a trusted supplier of Hi-Shrink Tape and Hi-Shrink Tubing. We serve a wide range of industries, from aerospace and wind power to electrical and sporting goods, with solutions that fit their exact needs.

If you don’t find exactly what you are looking for in our products, we will work closely with you to design and engineer a product that meets your needs while keeping your budget in mind. Most often, we are able to help our clients achieve their composite part manufacturing goals while also reducing production costs due to our tapes being thinner and stronger, thus requiring less material upfront and delivering reliable performance.

Contact our team today to get started or to request a complimentary sample of our Hi-Shrink composites release tape. We will happily ship a sample of an in-stock tape to you to evaluate in your production environment. If it requires modification, our engineering team will work with you to further tailor it to your specific application.