Not all heat shrink tape performs the same. Learn what makes high performance heat shrink tape different, and why the tailored shrink curve matters.

Read MoreAchieving Consistent Composite Part Quality Step by Step

Looking to improve composite part quality? We’re breaking down the manufacturing process to explain what’s most critical at each step.

Read MoreWhen to Use a Silicone Release Film

Learn about Silicone release film for taping and tubing applications, and when you might need this option over the more common PTFE.

Read MoreIncreasing Throughput in High-Rate Composite Manufacturing

Learn what’s driving high-rate composite manufacturing worldwide and what processes play a key role in meeting that demand.

Read MoreShrink Tape for Composites: Exploring 3 Small-Diameter Examples

Learn how shrink tape for composites is a common solution for small-diameter cylindrical parts, with three sporting goods examples.

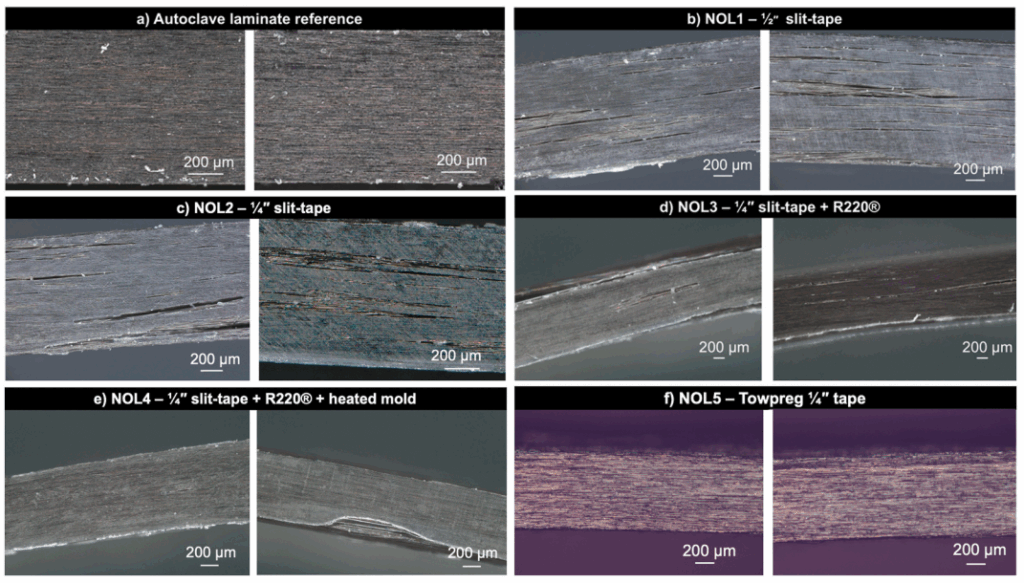

Read MoreEnhancing Composite Consolidation: How 220R Hi-Shrink Tape Improves CFRP Performance

Explore a valuable study about the impact of Dunstone Hi-Shrink Tape for enhancing composite consolidation and performance.

Read MoreShrink Tape vs. Vacuum Bagging vs. Autoclave

When you have composites and resins that need to be consolidated or laminated, it’s important to select the right process for your project. Typically, three options are the most common: shrink tape, vacuum bagging, and autoclaving. Let’s explore shrink tape …

Read MoreChoosing the Right Shrink Tape for Your Composite Overwrapped Pressure Vessel to Yield the Best Results

A composite overwrapped pressure vessel, or COPV, is used to store various types of gasses, water, or chemicals. One of the most common types of gas stored in COPVs is hydrogen. Hydrogen gas is stored under pressure in order to …

Read MoreWhy Heat Shrink Tape Thickness Matters

Heat shrink tape thickness is crucial to ensure the proper compression of your composites. See why heat shrink tape thickness is important.

Read MoreHow to Find the Best Polyimide Tape Supplier

Looking for a new polyimide tape supplier? Explore key variables that will impact part performance, costs, and more here.

Read More