What Actually Causes the Shrink Process?

While there are numerous details that all contribute to how shrink tape works, it ultimately comes down to two leading variables: material and temperature.

- Material — Common materials used in heat shrink tapes include polyester, ethylene tetrafluoroethylene (ETFE), and polyimide. Other films and materials are available, but these three in particular are the most common for heat shrink applications. Some materials are better suited for different resin systems and composite materials as well, and the overall intended output of the production process will determine which material is used.

- Temperature — The temperature at which a composite part is cured plays an equally important role as the material used to provide compression. Some materials require significantly higher temperatures, such as PEEK and PPS resin systems. For higher-temperature applications, the heat shrink tape used must be suited to perform in that temperature range; otherwise, the tape — and the compression on the composite part — will fail.

These two aspects make the greatest difference in how heat shrink tape works, but other details can influence the overall compressive force and end performance of the tape and the resulting product. These include:

- How tightly wrapped the tape is on a part

- How much over-wrapping is utilized

- How many layers of tape are applied

- How thick the tape is that is being used

- How strong the tape shrink force is

- How large the diameter of the part is

A Few Important Notes About Heat Shrink Tape

It’s important to understand that heat shrink tape — particularly Hi-Shrink Tape engineered and manufactured by Dunstone — is not an adhesive-backed tape. In virtually every instance, the adhesive is not needed thanks to the natural properties of the tape and its ability to be easily applied to a composite part before curing. Additionally, if an adhesive were to be used, it could adversely affect the resin/composite matrix at the chemical level. You can learn more about how to use heat shrink tape here to improve application performance.

Hi-Shrink Tape is also meant to be a processing aid and is not meant to be used for the life of the part. While there are some applications in which our tape remains on parts (electrical coils are one such example), most applications will require the tape to be removed — either via manual removal such as scraping and grinding or via an optional release coating that is available on many of our shrink tape products. The latter allows the tape to be easily removed after curing without leaving any residue behind. These coatings are available on one or two sides depending on the application.

What’s the best heat shrink tape for your application? Learn more here.

That’s a Wrap — Now Find the Right Tape for Your Goals

If one of your goals in the months and years ahead is to continually push the bounds of composite part quality and performance, there’s no better heat shrink tape solution than Dunstone’s Hi-Shrink Tape. We offer a full portfolio of Hi-Shrink Tapes — as well as Hi-Shrink Tubing — for a variety of applications. Below are some of our most popular solutions:

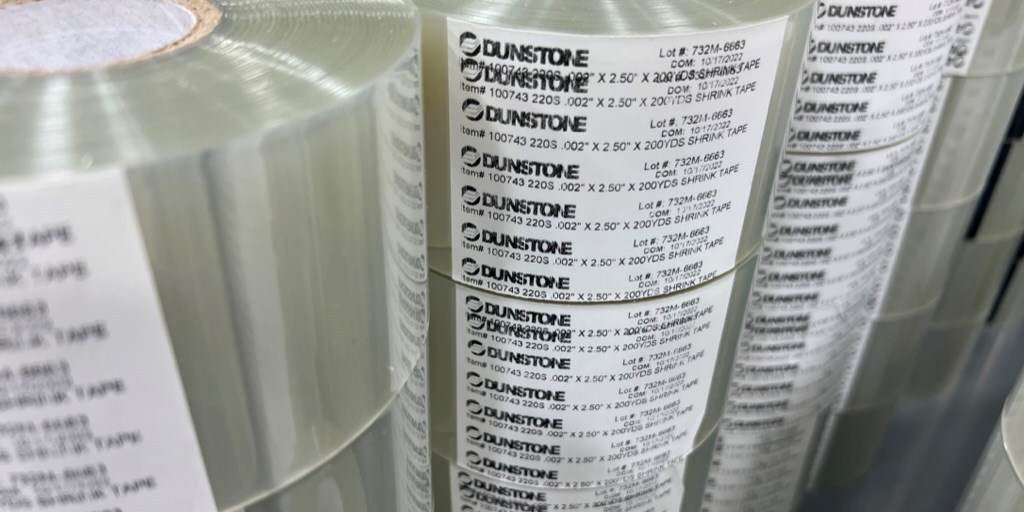

- 200 Series — At only .002” thick, our 200 Series is the Swiss army knife of our product line. It provides the most flexible characteristics while remaining one of our thinnest shrink tape materials and serving a range of curing temperatures. It’s available perforated and with and without release coatings on one or two sides.

- 500 Series — Our thickest Hi-Shrink Tape, the 500 Series provides our highest level of compressive force for those composite layups that need some serious muscle to get the resin systems properly implemented between composite layers. It’s commonly used with composite tubing, flexible ductwork, and silicone hoses and is available with or without release coatings.

- X Series — Our X Series provides one of the highest-temperature curing solutions available on the market today. Capable of providing compressing force at temperatures up to 400ºC / 750ºF, it’s often used for mechanical compression as well as dielectric insulation.

Find Your Perfect Heat Shrink Tape Solution

Explore the various series of Dunstone’s Hi-Shrink Tape in our free downloadable eBook and discover which one best suits your needs. Our blog breaks down the 200, 500, and X Series and provides more in-depth detail, helping you select the ideal tape for your application.

Talk to an Engineer About Your Application

Dunstone provides complimentary samples of our in-stock Hi-Shrink Tapes to help you determine viability and experience the advantages of our materials firsthand. Simply reach out to us and let us know the details of your application, then we’ll get a sample out to you right away.