Demand for Composite Parts is Increasing Globally

Around the world, demand for composite components is skyrocketing — particularly in the aerospace, automotive, and defense industries. Over the next five years, the market for composites — in the U.S. alone — is expected to increase by 50%, or around $10 billion.

As a result, organizations and partnerships are driving toward faster composite manufacturing and development. Examples include NASA’s Hi-Rate Composite Aircraft Manufacturing (HiCAM) project, which partners with the composite industry “to increase the rate of composite aircraft manufacturing, reduce costs, and improve performance.”

Concurrently, there is a notable issue with composites — they are often not recycled at the end of their lifespan. In the U.K., partnerships and programs — such as HVM Catapult — have sprung up to accelerate the recyclability and reusability of composites while also innovating more sustainable variations of common composite materials.

Examining Current Methods for High-Rate Composite Manufacturing

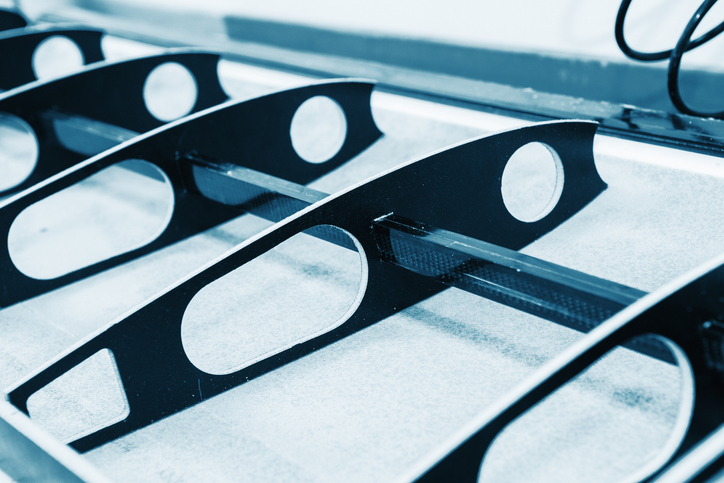

Today, manufacturers primarily use three methods for the production of composite parts: 1) autoclaves, 2) vacuum bagging, and 3) shrink films and tapes. All three apply pressure over time in order to consolidate composite materials/prepregs and resin in order to cure them and produce a part with a consistent finish and, ideally, no voids or defects.

There are a few challenges with these methods that get in the way of faster production. First, autoclaves are expensive and can only hold so many parts during their operating cycles. So, unless a manufacturer is prepared to spend tens of thousands (or more) on numerous autoclaves, going this route to streamline high-rate composite manufacturing won’t be ideal.

Vacuum bagging is another alternative to consolidate composite parts, but it is also an extremely cumbersome process. Additionally, vacuum-bagging is limited to certain pressure levels, so it may not be ideal for applications that require extreme pressure or high temperature during curing.

Additionally, composites can be manufactured much more quickly by eliminating the need for autoclave curing and allowing parts to be welded instead of mechanically fastened or bonded. Advanced welding techniques such as resistance and induction welding enable rapid, localized heating for joining components in minutes. These processes are highly automation-friendly, reduce part count, and streamline assembly by supporting integrated, net-shape designs. Together, these benefits cut cycle times, lower energy use, and make high-rate production of composite parts more viable.

Why Shrink Tape is Ideal for High-Rate Composite Manufacturing

While an autoclave or vacuum-bagging process may be ideal for some applications, countless composite parts can benefit from shrink tape. There are numerous reasons for this:

- Flexibility in application — One of the key advantages of shrink tape is that it can be applied in a variety of ways depending on the part and the performance needed from it. For example, if greater compaction is required based on the material and resin system, the tape simply needs to be applied with more overwrap, additional layers, or more tension. Learn more about application techniques here.

- Automation capability — Whereas autoclaves and vacuum-bagging require manual effort (putting parts inside these systems, taking them out, etc.), shrink tape can be automatically applied to parts through the use of winders. This rapidly accelerates the process of applying the tape, allowing for higher throughput.

- Lower cost — Shrink tape is exceptionally thin, yet thanks to its design and composition, it applies significant shrink force to underlying parts. As a result, manufacturers spend less buying shrink tape than investing thousands into autoclave systems and other tools. All that is needed is an oven to cure the composite, which is much less expensive than an autoclave, depending on its size.

- Customization — Shrink tape is extremely customizable. If greater shrink force, a higher overall shrink percentage, specific thickness, or any other property needs to be modified, shrink tape is fully capable of handling adjustments. This further streamlines production processes and ensures the tape works exactly as needed.

- Availability — At Dunstone, dozens of Hi-Shrink Tape products are in-stock and ready to ship. We keep a full suite of Hi-Shrink Tapes ready, whether it’s our thinnest 100 Series tape, our 200 Series (a “Swiss Army knife” solution for numerous applications), our high-force 500 Series, or our X Series industry-leading high-temperature solution, we have the shrink tape you need ready to go.

Request a Complimentary Sample — and Get Ready to Transform Your Composite Manufacturing Process

We are happy to provide a complimentary sample of our in-stock Hi-Shrink Tape products. Simply reach out and let us know some details of your application, then we’ll get a sample out the door for testing. If you need to further refine the tape for your application, our engineers are available to develop something specific — reach out to us here to get started.