Understand the Behavior That Separates High Performance Heat Shrink Tape From Traditional Compaction Films

Not all heat shrink tape performs the same when it matters most. The term “high performance heat shrink” isn’t marketing language; it describes how shrink tape behaves during the critical curing phase when resin viscosity drops and maximum compaction is essential. While traditional compaction films apply pressure only during wrapping, high performance heat shrink tape is engineered to deliver increasing force precisely when your composite part needs it.

The Traditional Compaction Film Problem

For decades, manufacturers have relied on standard compaction films like cellophane, woven nylon, and polypropylene to consolidate composite parts during cure. These materials work by applying tension during the wrapping process; operators wrap them tightly around the part, creating initial compression through mechanical tension alone.

The challenge emerges as soon as curing begins. These traditional films relax as temperatures rise, losing compressive force right when it’s needed most. At room temperature during layup, resin viscosity is at its highest and is difficult to move. But as the part enters the oven and temperatures climb toward 120-165°C, the resin reaches its lowest viscosity point and begins to flow. This is the critical moment when maximum compression should be applied to eliminate voids, remove volatiles, and ensure proper lamination between layers. Traditional films, however, provide their weakest compression at this exact phase.

The High Performance Difference: Engineered Shrink Behavior

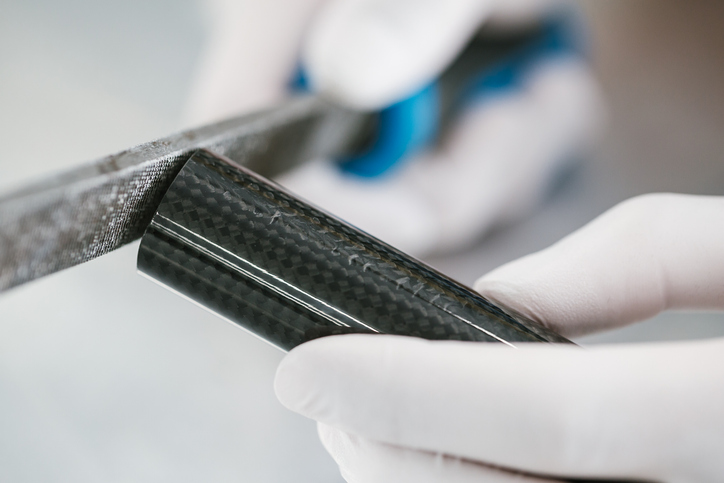

High performance heat shrink tape functions on an entirely different principle. Rather than relying solely on application tension, these tapes are engineered with a tailored shrink curve that matches the thermal profile of composite curing processes.

Dunstone’s Hi-Shrink Tape begins shrinking at approximately 70°C and reaches maximum compressive force in the 120-180°C range — precisely when resin viscosity drops and flow occurs. This isn’t coincidental. The molecular structure of the tape material is designed to create this behavior, delivering a compression curve that rises as temperature increases rather than falling away.

The force delivered depends on several engineering variables. High performance heat shrink tape can apply anywhere from 1.65 to 21.64 pounds of shrink force, with the exact amount determined by tape thickness, shrink percentage, application tension, and overlap. Tape thickness ranges from 0.001 inch (1 mil) for applications requiring minimal force to 0.005 inch (5 mils) for parts demanding maximum compaction. Shrink percentages typically range from 5% to 20%, with higher percentages generating greater compressive force.

Material composition plays an equally critical role in performance. Polyester-based tapes (100, 140, 200, 300, and 500 Series) handle cure temperatures up to 165°C and serve the majority of composite applications, from automotive drive shafts to aerospace components. For higher temperature requirements, ETFE-based tapes extend performance to 180°C, while polyimide materials enable shrink behavior at temperatures reaching 400°C for advanced thermoplastic systems like PEEK and PPS.

What This Delivers in Practice

This engineered thermal behavior translates directly to part quality. As the tape shrinks during cure, it eliminates voids between composite layers, removes air pockets from the resin matrix, and ensures a consistent surface finish across the entire part. The continuous compression throughout the cure cycle prevents the formation of dry spots and foreign object debris that compromise mechanical strength.

Because high performance heat shrink tape is significantly thinner than traditional compaction materials while delivering superior force, manufacturers use less material overall. A 0.002-inch polyester tape at 50% overlap can outperform multiple layers of thicker materials and cheaper non-shrink films, reducing both material costs and removal time after cure.

Applications span from small-diameter sporting goods like arrow shafts and golf clubs to large composite tubes, pressure vessels, and high-voltage electrical coils. In each case, the tailored compression curve ensures optimal consolidation regardless of part geometry or resin system.

Performance Is About Physics, Not Marketing

High performance heat shrink tape earns its designation through measurable engineering characteristics, specifically, the ability to apply increasing compressive force during the phase when composite parts are most vulnerable to defects. The tailored shrink curve that begins at 70°C and peaks at optimal curing temperatures represents decades of material science development focused on matching tape behavior to resin cure profiles.

For manufacturers evaluating compaction solutions, the question isn’t whether their current process “works” — it’s whether a material engineered for peak performance during cure could deliver better results. Testing high performance heat shrink tape with your resin system in your specific application is how you verify the difference.

We can even help you determine which shrink tape is best suited for your application, based on what you’re currently using and modeled sample data. Request a complimentary sample to evaluate performance in your production environment.