Don’t Risk the Residue

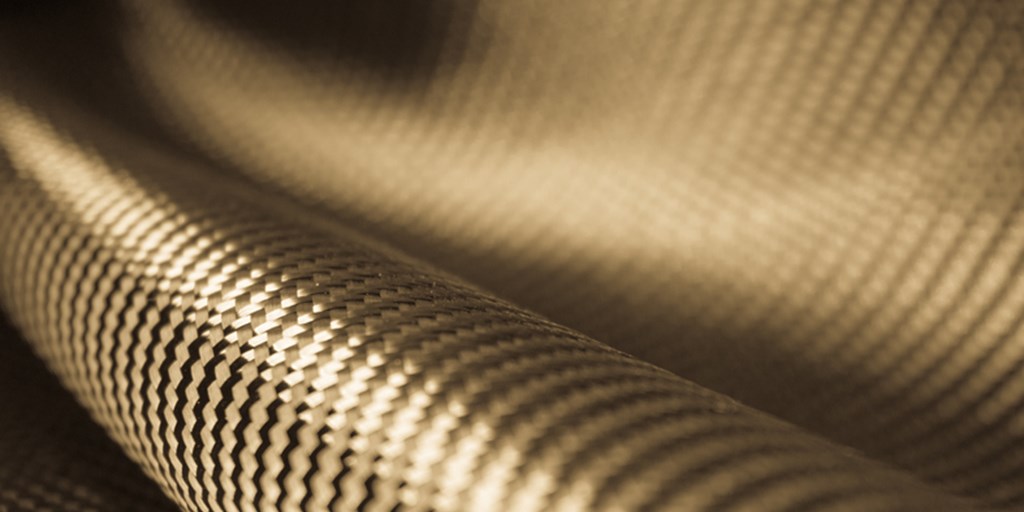

Depending on your application, you may be in need of an adhesive heat shrink tape for applying compressive force to your composite parts and products. Whether you’re looking to produce pipes and hoses for fluid or gas transfer, components for vehicles or aircraft, or any other number of solutions calling for compressive force to ensure product quality, it’s clear that a heatable compaction film or tape is needed to create the desired results.

But when it comes to achieving the quality and other material properties you want in your composite products, the last thing you need is an adhesive heat shrink tape. Adhesives can leave residue or other traces on your products after the curing process. Additionally, the adhesive itself may fail as the temperature rises, causing the tape to fail or creating negative effects due to chemical reactions between the tape and the resin.

Fortunately, you don’t need an adhesive heat shrink tape to ensure a consistent, resin-rich surface finish that’s free from voids, foreign object debris (FOD), and other unwanted elements. At Dunstone, we offer a complete line of Hi-Shrink Tape products in a variety of thicknesses, widths, and interior diameters (IDs) and with a wide range of curing temperatures, shrink percentages, and other valuable traits — all without any adhesives or residues.

Here, we’ll cover some of the key advantages that our Hi-Shrink Tapes provide. If you’d like to talk with one of our application experts about your part needs, simply reach out to us here. We’ll be happy to help.

Release Characteristics and Coatings

First and foremost, how is it that our Hi-Shrink Tapes work without the need for adhesive? It all starts with the materials the tapes themselves are made from. At Dunstone, we use polyester (Mylar), ethylene tetrafluoroethylene (ETFE), and polyimide. These materials feature natural release characteristics, allowing them to be removed from a part after the curing process — if the tape is meant to be removed at all. In cases where the tape serves as an insulative layer, it can simply remain on the product after curing. We also offer many of our tapes with release coatings on one or two sides depending on the application. These coatings ensure the tape is cleanly removed from the part, leaving behind a smooth finish. Application is easy. The tape can be secured to the part initially by winding a few wraps of the tape tightly over itself. Continue spiral wrapping the tape down the length of the part, and then secure the final end of the tape with a few wraps of an adhesive tape, like masking or flash breaker tape.

High-Temperature Shrink Capability

Depending on the application, you might have a need for a high-temperature shrink film. This is common with thermoplastic resin systems where curing temperatures can be anywhere from 180ºC (356ºF) up to 400ºC (752ºF). To support these production needs, Dunstone offers two high-temperature heat shrink tapes in our 212 HT and 208X lines. A multilayered shrink tape, our 212HT line addresses the lower end of this temperature range while also providing exceptional flexibility for parts with complex shapes and angles. The 208X is the highest-temperature shrink tape available on the market, serving applications requiring cure temperatures well into the 300ºC range and above. Many adhesive heat shrink tape options would have failed well before these temperatures, yet Dunstone Hi-Shrink Tape continues to provide compaction on the same tailored curve as our other Hi-Shrink Tapes.

Perforations

In some applications, various volatiles and gases must be permitted to escape the wet layup. If they weren’t able to out-gas (escape) during the curing cycle, they could create air pockets, voids, de-lam, and other unwanted effects on the surface or deeper down in the laminate layers — causing product quality and appearance issues. To solve for this, Dunstone offers many of our Hi-Shrink Tapes in perforated variations. These perforations consist of tiny punched holes on quarter-inch staggered centers along the length of the tape. This allows the vapors and gasses to escape the layup, resulting in a stronger product and resin-rich surface. Learn more about perforated tape, what it’s meant to do, and what it’s not meant to do here.

Customization

While we offer many Hi-Shrink Tape solutions that can serve as a ready replacement for adhesive heat shrink tape, not every application can rely on the same products. Different materials, resin systems, and product performance and appearance goals mean you might need a completely customized solution. To help you achieve the right outcome, Dunstone proudly offers customization services on our Hi-Shrink Tapes. Our team will happily review any existing materials and processes you’ve been using and will then develop a solution to solve your respective challenge. With decades of experience, our engineers will not only provide a shrink tape that will work for your application but one that will also meet your respective budget requirements. Learn more about our custom solution services here.

If Adhesive Heat Shrink Tape Isn’t Producing the Results Needed, Trust the Solution to Dunstone

Our Hi-Shrink Tapes have become the solution of choice for numerous companies across multiple industries worldwide. Connect with our team today to learn more about our capabilities and to request a free sample of a shrink tape suited to your application.