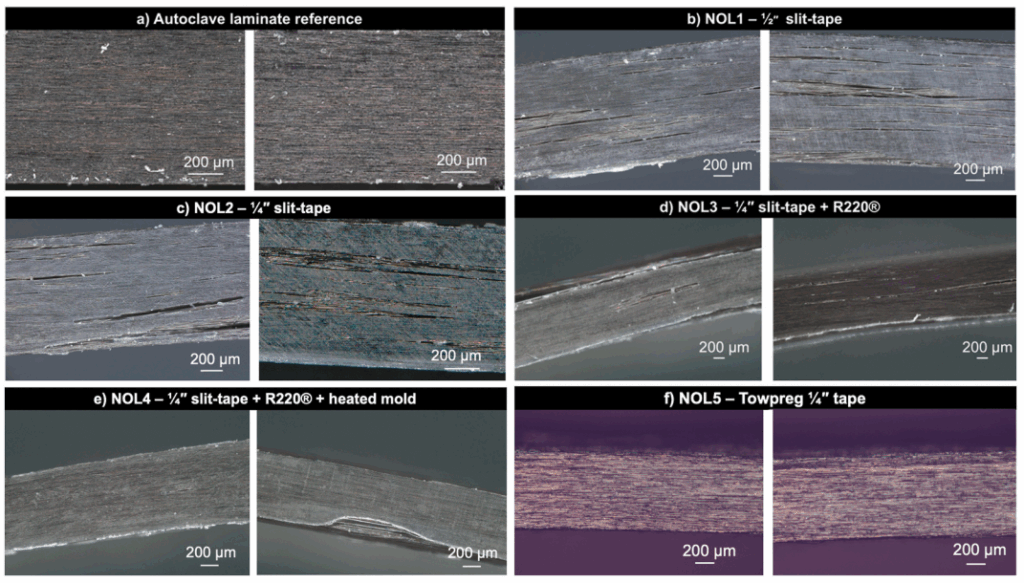

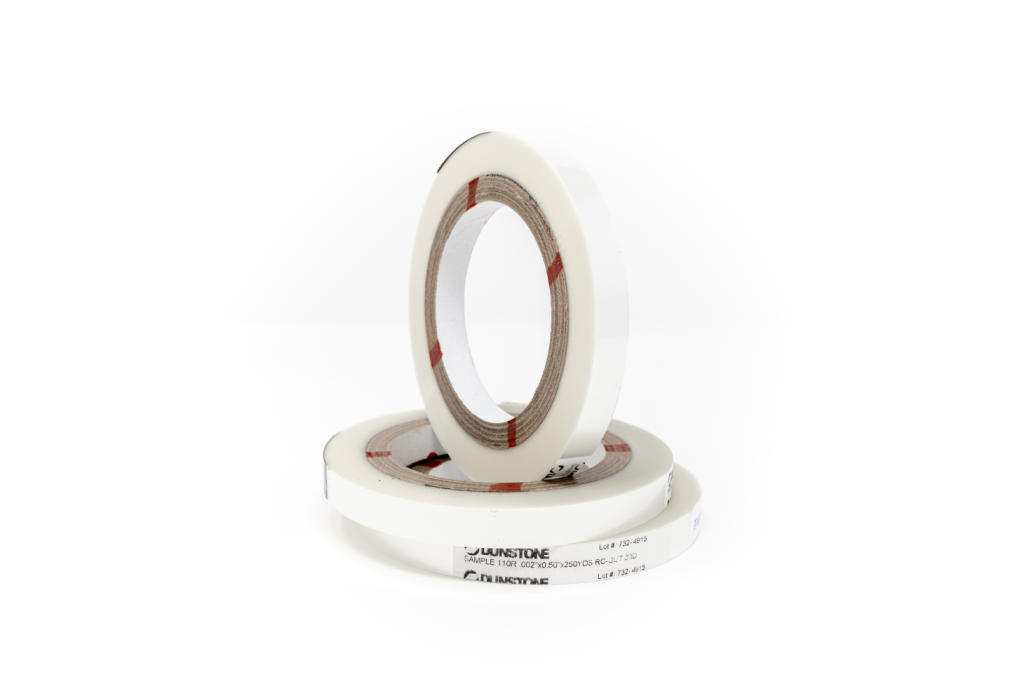

Explore a valuable study about the impact of Dunstone Hi-Shrink Tape for enhancing composite consolidation and performance.

Read More

Expert Insights to Take Your Production to the Next Level

The Role of Shrink Tape in Composite Part Manufacturing

Composite part manufacturing requires heat shrink tape in order to properly compress products. Heat shrink tape solutions can provide many benefits during manufacturing of composite parts, including removing voids, improving lamination, and providing a superior surface finish. Let’s explore the …

Read More

How to Eliminate Defects in Composites

Composites are crucial to a wide range of industries. From sporting goods to oil and gas to automotive, various applications require composites for their numerous benefits. However, there can be some defects in composites that impact the function and safety …

Read More

Shrink Tape vs. Vacuum Bagging vs. Autoclave

When you have composites and resins that need to be consolidated or laminated, it’s important to select the right process for your project. Typically, three options are the most common: shrink tape, vacuum bagging, and autoclaving. Let’s explore shrink tape …

Read More

Construction Shrink Wrap Tape: Applications, Benefits, and Solutions

Construction and civil engineering projects need to have high-quality, durable materials that will function properly for decades. From composite poles and beams to building reinforcements and more, it is critical to ensure that your products and materials are properly consolidated …

Read More

What Is Heat Shrink Tape?

Heat shrink tape is used in various applications and industries to compress products and structures. When heat is applied, the heat shrink tape applies compressive forces without relaxing throughout the curing process. These powerful compressive forces can be used to …

Read More

A Complete Guide to Hi-Shrink Polyester Shrink Tape: Features, Uses, and Application

Hi-Shrink polyester shrink tape is critical to the function and efficiency of many industries, including the automotive, oil and gas, marine, composites, and sporting goods industries. These solutions provide various advantages to each of these industries through their many beneficial …

Read More

Choosing the Right Shrink Tape for Your Composite Overwrapped Pressure Vessel to Yield the Best Results

A composite overwrapped pressure vessel, or COPV, is used to store various types of gasses, water, or chemicals. One of the most common types of gas stored in COPVs is hydrogen. Hydrogen gas is stored under pressure in order to …

Read More

Why Heat Shrink Tape Thickness Matters

Heat shrink tape thickness is crucial to ensure the proper compression of your composites. See why heat shrink tape thickness is important.

Read More