Learn What Influences the Compaction Strength of Our Products

-

Tape Thickness

The thicker the tape used on the part, the more compressive force is applied as it shrinks. Dunstone Hi-Shrink Tapes are available in thicknesses ranging from 0.001 in. (0.025 mm) up to 0.005 in. (0.125 mm). Explore our various shrink tapes here.

-

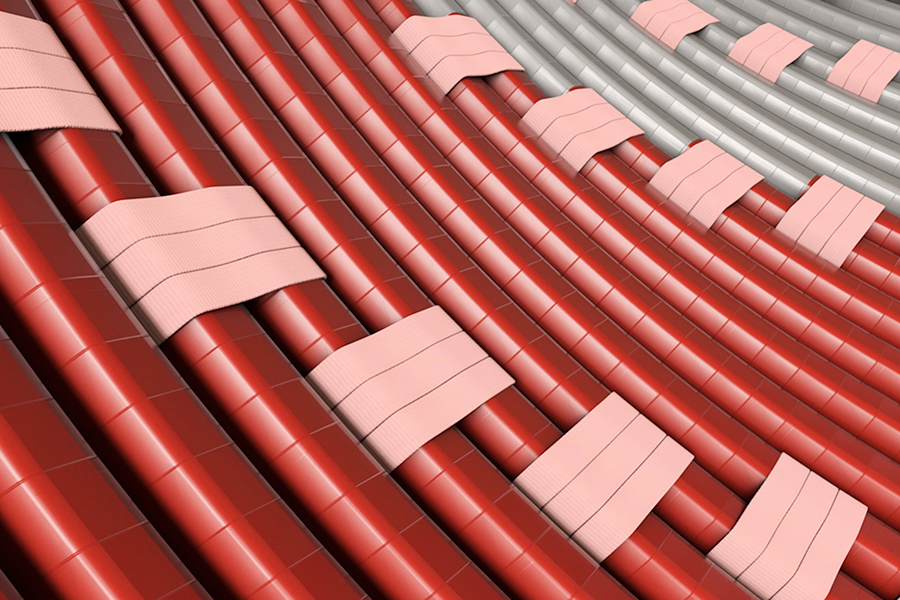

Number of Layers of Tape

The number of Hi-Shrink Tape layers used follows the same principle as above because more layers means a thicker overall layer of tape around the part. Greater compressive force will be applied to the part with more layers.

-

Shrink Percentage of the Tape

The higher the shrink percentage of the tape, the higher the shrink force applied to the part. Dunstone offers Hi-Shrink Tapes with shrink percentages ranging from 5% up to 20%. Explore our shrink tapes here.

-

Taping Tension

Increasing taping tension increases the compressive force on the part. Applying the tape under tension will immediately begin to compact the part. When the tape begins to shrink under the application of heat, the compaction force applied to the part will increase further. Learn more about how to properly apply shrink tape in this video.

-

Part Diameter

Inversely related to compaction force, the larger the diameter of the part being wrapped, the lower the compaction. Large diameters usually require thicker tapes and/or more layers of tape to achieve desired compaction. Contact us if you have questions regarding a large-diameter application.