What’s the difference between shrink percentage and shrink force?

Shrink percentage is a measurement of the machine direction (MD) shrinkage of Hi-Shrink Tape. We offer shrink percentages from 5–20% in most of our films. Shrink force, also called shrink tension, is the force exerted by the tape as it shrinks. It is measured in lbs/force per inch of width. Note that shrink percentage is not always related to shrink force — some products with a higher shrink percentage will exert little to no shrink force (and vice versa).

Which tape should I start with?

Individual applications vary greatly, so please contact us with the details of your application. You can also view the available tape options from our Hi-Shrink Tapes main page where they are sorted by film thickness and temperature class. Additionally, you can request a sample to evaluate in your production environment.

Do you have a tape that can be used for high-temperature cure cycles common with thermoplastic resin systems?

We offer either an ETFE or a polyimide shrink tape for high-temperature cures. Which one you will need will depend on the your cure temperature and how much compaction force you require. Please check out our Hi-Shrink Tapes page to select a tape based on temperature requirements.

I use a non-shrink tape and still have voids in my composite wall. Can your Hi-Shrink Tape help?

Dunstone can solve a void problem with our Hi-Shrink Tape. Contact us to discuss the application, and we can send a sample for evaluation.

At what temperature does Hi-Shrink Tape start to shrink?

The shrink initiation temperature for our tapes is 65°C (150°F). Max shrink percentage and shrink force are typically achieved between 120–150°C (250–300°F).

Does Hi-Shrink Tape have adhesive on one side?

No. Hi-Shrink Tapes are non-adhesive films and in most applications are intended to be removed from the part after cure.

How do you apply Hi-Shrink Tape to the part?

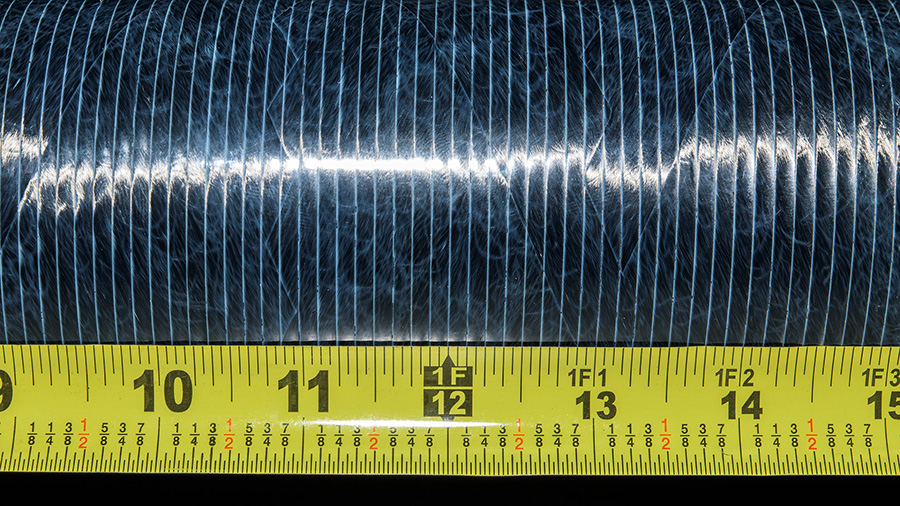

Hi-Shrink Tape is applied by spiral wrapping the tape over the outer surface of the part. The starting end of the tape can be secured with an initial wrap over itself, or by using a small piece of adhesive tape to hold it in place. Continue to wrap the tape in a spiral manner around the circumference of the part, moving lengthwise down the part with each successive wrap. Be sure to wrap each subsequent layer of tape on itself with the same degree of overlap (see Figure 1 below). If you’re not sure how much overlap to use, start with 50% and then determine after part cure if you need more or less compaction force. If more force is required, increase your overlap percentage. Decrease overlap if less force is required. Watch our video on how to use heat shrink tape here.

What should my taping tension be?

Most users are applying between 5 and 8 lbs. of force when taping. No matter what your taping tension is, it is important to try and maintain consistent and even tension during the taping process. Variations in taping tension can lead to variations in compaction force, the end result being visual defects on the part surface and possibly porosity issues within the composite layers themselves. There are 2 methods for applying the tape: by hand, or with automated taping equipment. When taping by hand, a good rule of thumb is to keep the tape “snug” against the part surface, avoiding any loose wraps of film. This should give you a clean, consistent part surface after the tape is removed. When taping with automated equipment, it is much easier to maintain consistent and specific target tension numbers, as the equipment is doing it for you. Refer to the variables affecting compressive force page or contact us if you have further questions about taping tension or making adjustments to improve part quality.

I’m using a wet-wind process or have a very resin-rich prepreg. Do I need to use a perforated Hi-Shrink Tape to squeeze out extra resin?

Probably not. It is very common to see resin bleed out between the layers of tape. The cured resin on the tape outer surface should not interfere with the removal of the tape. The perforated tape is normally used when the curing resin system is out-gassing volatiles or water vapor, and it helps those gasses escape from the surface of the part. Learn more about perforations here.

Does the tape stick to the part?

It’s not supposed to stick. We offer our Hi-Shrink Tapes in non-coated and release coated versions. See our Hi-Shrink Tapes page for S (standard non-release coated) and R (PTFE release coated). Silicone release coatings are also available.